Key Principles of Customize Pipe Support Program

eryar@163.com

Abstract: The article show one customize pipe support method in AVEVA Marine/Plant. Follow the method you can create a pipe support modeling program to meet your company’s specific need.

Key Words: AVEVA Marine, AVEVA Plant, PDMS, Pipe Support, PML

I have already used AVEVA Marine for years. It is convenience and efficiency. But only the MDS module does not meet our design standard. There are so many pipe support models in the database, in order to meet the plant and marine pipe support design requirement. When creating a support model, you must wait for a while for the program to find the needed support, it's so boring. So I decided to develop a support program by myself.

To do such a program, you must know the knowledge below:

l The Design Element Hierarchy

l Event-Driven Graphics Utilities

l How to create component and specification in paragon module

l PML (the AVEVA Programmable Macro Language)

l General Commands for Creating the Model

1. The Design Element Hierarchy

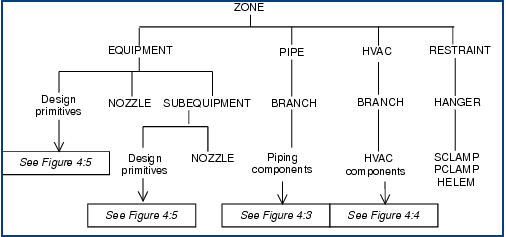

Figure 1.1 The Equipment and Piping hierarchy

The hierarchy is very important concept in AVEVA productions. It restricts that which element can hold what elements.

To know all data model and its attributes in AVEVA software, you can see the "Data Model Reference Manual" for reference.

2. Event-Driven Graphics Utilities

Event-Driven graphical interaction allows cursor picks in 3D views to be used intelligently as part of some overall rather than just being used for navigation or element identification purposes.

Once you have selected an option which puts you into event-driven graphics mode, such as measuring distances between calculated positions, you can carry out unrelated actions using non-graphical forms and menus without interrupting the logical sequent picking actions.

When you are in event-driven graphics mode, a Positioning Control form lets you control how your pointer picks are translated into the coordinates of required positions (which need not be at the actual cursor position).

Click in the 3D View and then press the Esc key to leave event-driven graphics mode.

Note: EDG functions are not available within Model Editor mode.

When use the Distance Measure from the toolbar, a Positioning Control will display automatically.

Figure 2.1 Distance Measure on the Utilities toolbar

Figure 2.2 Positioning Control

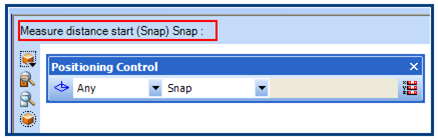

In PML, the object EDGPACKET is used for this facility. You can reference to : componentcreation.pmlfrm for detail. I will list the simplest code to demonstrate the utility.

To use your own PML program, you can put the following code in a text file named pickdemo.pmlfrm, and put it to the PMLLIB path, my PMLLIB path is set to :

D:\AVEVA\Marine\OH12.0.SP6\PMLLIB\AddIns.

Then in the Design module's command window input the command:

PML REHASH ALL

SHOW !!pickdemo

List 1 : The simplest PML code for Event-Driven Graphics pick

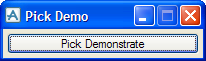

When the command : Show !!pickdemo applied, the pick demo form will show like follow:

Figure 2.3 Pick Demo Form

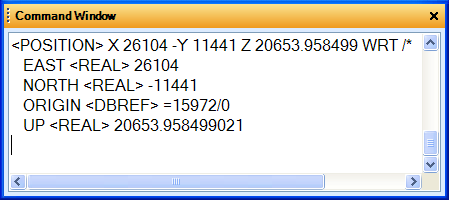

When you push the button and pick a flange model, the information will display in the Command Window like follow figure:

Figure 2.4 Position in the Command window

3. Create Component and Specification

Like the pipe model in Design Module which its components are all from paragon database, we will save our support model in paragon database too. This is also MDS does.

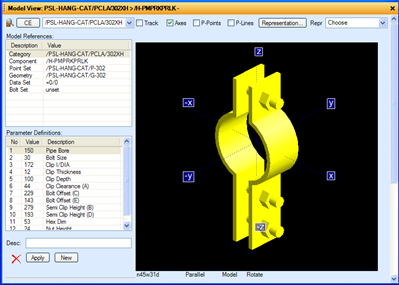

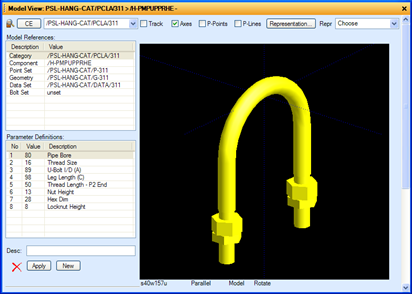

You can save the pipe clamp data:

Figure 3.1 Pipe clamp model in paragon

Figure 3.2 Pipe clamp model in paragon

After doing this, you add specifications for support component like pipe component, so you can use the support via the specification.

For more information about Catalogues and Specifications please see: Catalogues and Specifications Reference Manual.

4. PML

You can learn more from the manual: Software Customisation Guide.

The manual describes how to use PML, the AVEVA Programmable Macro Language. You should use it together with the Software Customisation Reference Manual.

You do not have to be a professional programmer to start to learn PML,

although you may find the manual difficult to follow unless you have

some understanding of programming concepts such as if statements and

do loops. If you have no programming experience, you should consider

attending a PML Training Course. For details, contact your local support office, whose address is given on the AVEVA website.

5. General Commands for Creating the Model

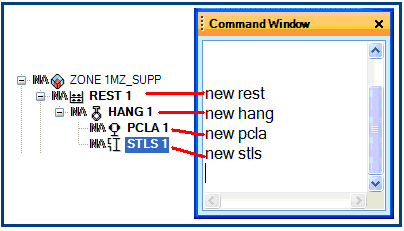

You can use the command: NEW to create new element. The command also can be used in PML.

Figure 4.1 Use new command to create element

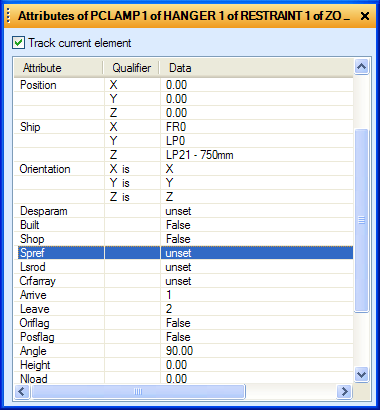

Then assign the spref and position attribute and others to the element, the spref attribute set for component's shape and position attribute set for the component's position.

Figure 4.2 Attributes of the component

You can use PML command:

SPREF /Your_Support_Specification

/Your_Support_Specification is created in the paragon module.

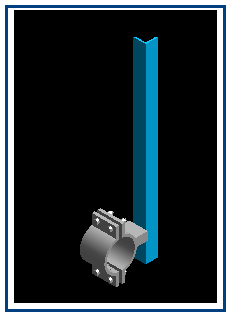

The result is in the below picture:

Figure 4.3 Support model in Design module

So if you understand the 5 key principles you can build your support models by your own program, this will be wonderful. When the pipe supports models are build, then can generate pipe support sketches and material automatically.

Enjoy!

If you find any mistakes or have any suggestions, feel free to contact with me: eryar@163.com.